Extending the Value of Mines by Recovering Copper From Low-Permeability Leach Pads

292+

injection wells and 80 monitoring wells drilled since 2013.

1

billion

gallons of acid solution is pumped through the wells annually.

2.5

million

pounds of additional copper are extracted from the mine each year as a result of our methods.

When a copper mine reaches the end of its life, it often still contains huge amounts of unextracted metal. The Carlotta mine in Arizona faced a critical challenge – millions of pounds of copper remained locked in its, 70-meter leach pads with no safe way to get it. Our advanced techniques targeted these areas from below the surface, allowing the recovery of the remaining copper and adding years to the mine’s life.

The Challenge

Over years of mining, the leach pads at the Carlotta mine had accumulated vast amounts of trapped copper. Conventional techniques weren’t suitable because of severely crushed ore layers restricting acid solution flow. The operators were facing the prospect of having to leave an estimated $300 million dollars worth of copper unrecovered on the site. A specialized approach was needed to enhance recovery without endangering site stability.

The Solution

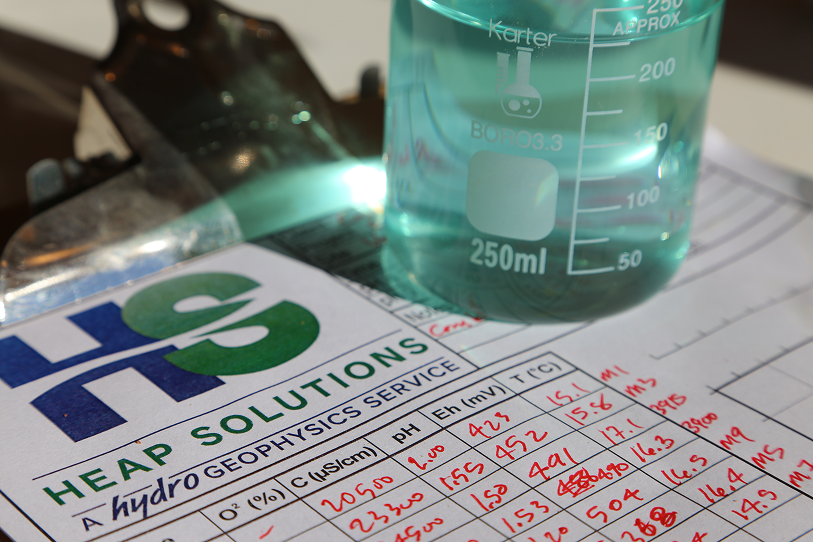

Our custom approach uses electrical resistivity geophysics to map ore permeability and design a strategic well field. By adapting methods used in the gold industry, we use low-pressure PVC-cased injection wells that work well in this challenging environment. So far, we have drilled 292 injection wells as well as optimizing acid flow, and monitoring system impacts in real time. Without this enhanced recovery project the mine would have closed, leaving 50-100 million pounds of copper locked inside.

Why Certerra?

We’ve been helping to design, monitor, and verify the effectiveness of subsurface leaching projects in gold, copper, and silver heap leach pads for nearly two decades. We design custom solutions to address each site’s unique challenges. Working in partnership with our client allowed us to innovate, manage risk effectively, and refine techniques to extend the mine’s life. We have now used this method to create similar results on 22 different mines globally.

“These surveys were instrumental in developing non-conventional leaching methods to efficiently access previously “dry” and non-accessible areas within the leach pad. The leaching methods developed and continuous use of geophysical surveys resulted in overwhelming success to extract copper that would have been unrecoverable.”

Lynn Holden, Senior Manager, Technical Services, KGHM